Semiconductor Startups Innovate Personalized Medicine and High-End Wireless Products

Silicon Catalyst Helps Chip-Based Startups Develop Transformative Solutions

After Rick Lazansky earned a master’s degree in computer science at Stanford, he launched a series of startups. One went public, and two were acquired, giving him the resources to start investing in other startups. But about a decade ago, he grew concerned about the dearth of new hardware companies in the United States. Venture capitalists were not investing in semiconductor startups, and Silicon Valley was no longer known for silicon.

“Throughout my time at Silicon Catalyst, I’ve never heard anyone ask for anything but MATLAB for their system modeling and product development needs. It really is the gold standard in the industry.”

Richard Curtin, managing partner, Silicon Catalyst

So, nearly a decade ago, Lazansky and two colleagues, Mike Noonan and Dan Armbrust, launched Silicon Catalyst, an incubator and accelerator that helps its member companies pioneer semiconductor-based solutions. Silicon Catalyst assigns a senior partner to work closely with each member company for two years and provides its startups access to a comprehensive ecosystem of industry experts and advisors to fuel their business growth. The company’s collaboration with investors has resulted in hundreds of millions of dollars in funding for its member companies.

Silicon Catalyst also has strategic partnerships with corporations, and dozens of in-kind partners provide goods and services to the startups. These include semiconductor foundry TSMC, silicon design tool supplier Synopsys, and MathWorks, which provides modeling and simulation tools for algorithm development and system-level design. “Throughout my time at Silicon Catalyst, I’ve never heard anyone ask for anything but MATLAB for their system modeling and product development needs,” says Richard Curtin, a managing partner at Silicon Catalyst. “It really is the gold standard in the industry.”

MathWorks supports startups in programs like Silicon Catalyst with software access, engineering support, and brand awareness opportunities. The software includes tools that can generate C code from MATLAB® code. This provides an environment where MATLAB algorithms seamlessly work on a chip yet to be released. The startups can test their designs before the chip is ready. Startups can also access software to generate synthesizable HDL from MATLAB functions or Simulink® models.

Silicon Catalyst companies are developing new semiconductor solutions. They specialize in various areas, including 5G, artificial intelligence and machine learning, ultra-wideband (UWB), comms infrastructure, photonics, IoT, power, medical, MEMS and sensing, and semiconductor materials.

“It’s plug-and-play. Everything works. It’s not going to be a bunch of different software you’re trying to cobble together. Using MATLAB and Antenna Toolbox helped us shrink the design cycle.”

Raphael Guimond, antenna designer, SPARK Microsystems

Bouncing Around the Room

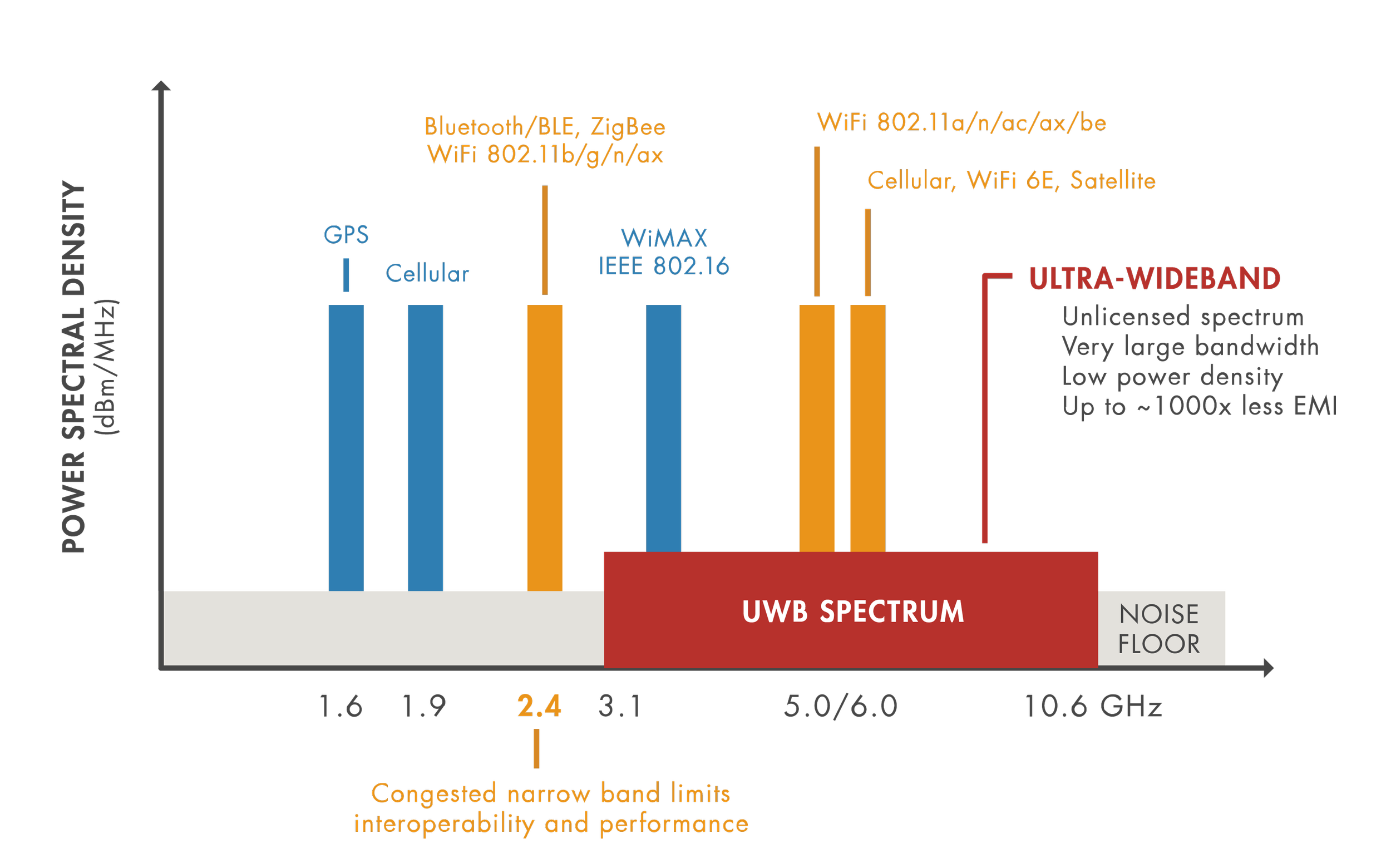

One startup in Silicon Catalyst’s program, SPARK Microsystems, creates UWB wireless transceivers. UWB communication takes place in frequencies between 3 and 10 gigahertz and is well-suited for short ranges. While most suppliers concentrate on the accurate ranging capabilities of the UWB spectrum, SPARK has focused on data communication applications. SPARK developed technology with lower latency, higher bandwidth, and lower power as a complement to existing personal area network alternatives such as Bluetooth®. Applications include high-quality uncompressed wireless audio, responsive gaming, virtual and augmented reality, and a variety of wireless sensor and presence detection applications in IoT.

SPARK developed a family of transceiver chips that can each transmit at 10 megabits per second. Among other customers, the company is partnering with various high-end gaming HID and audio device makers who are at various stages of deploying SPARK technology. As an example, SPARK has partnered with Sonus faber on high-end speakers. Its transceivers can transmit audio up to 8 meters without compression, enabling the delivery of high-quality audio performance at very low latency that is not achievable with Bluetooth or Wi-Fi®.

Another interesting application for SPARK technology is demonstrated by the luxury watchmaker, Platonum. Platonum selected SPARK UWB technology to provide ultra-low-latency and low-power, real-time data streaming for its smartwatches.

SPARK’s UWB technology has lower latency, higher bandwidth, and lower power requirements than other UWB systems.

(Image credit: SPARK Microsystems)

“We live and breathe short-range communication,” says Raphael Mehrbians, SPARK’s CMO and head of operations.

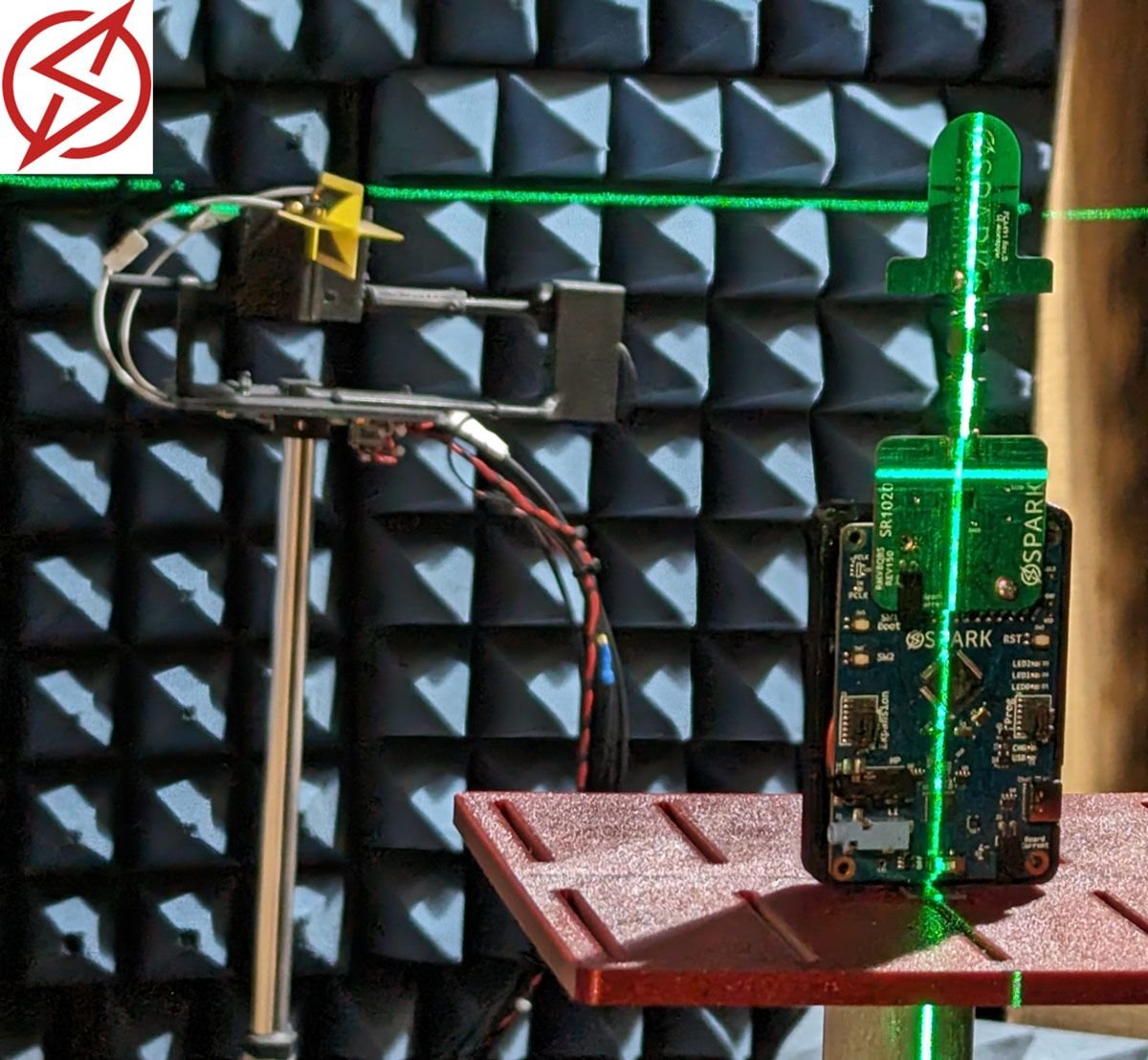

Raphael Guimond, an antenna designer at SPARK, says his team uses MATLAB for several tasks, including automated testing. The Federal Communications Commission regulates electronic transmissions and limits the amount of power that devices can broadcast at various frequencies so that they don’t interfere with other devices. To test transceivers, Guimond places them on a platform in an anechoic chamber, whose walls absorb radio waves rather than reflecting them. A spectrum analyzer is connected to an antenna in the chamber and sends data to a computer running MATLAB. Guimond uses Instrument Control Toolbox™ to rotate a turntable that holds the transceivers and to measure emissions at every angle. When measuring the radiofrequency emissions from a chip, the design team needs to subtract the losses from the wiring and connectors around it. They automate the process with MATLAB.

An anechoic chamber is extensively used to verify SPARK transceiver RF performance and robustness.

(Image credit: SPARK Microsystems)

Arranging the antennas in parallel and operating them in the same phase increases transmission power. Guimond also uses MATLAB for phased arrays and beamforming. Beamforming adjusts their phases relative to one another, focusing the transmission in one direction. That’s helpful when someone wearing wireless headphones is walking around a room.

The team at SPARK also input various propagation models, such as channel and ray tracing, into MATLAB. Predicting how a device’s signals will propagate in various environments allows SPARK to select the right antenna and optimize its placement and orientation in the device.

Guimond says one advantage of MATLAB is that it contains so many built-in tools. “It’s plug-and-play,” he says. “Everything works. It’s not going to be a bunch of different software you’re trying to cobble together. Using MATLAB and Antenna Toolbox™ helped us shrink the design cycle.” He’s excited about its potential to help deploy UWB. SPARK’s tech is “a pretty big move forward in terms of wireless technology,” he says.

Mehrbians says Silicon Catalyst has helped in several ways. “These include facilitating supplier and partner relationships as well as offering other advisory and marketing resources and tools that are extremely useful for startups,” he says, “as well as the whole advisor network, which has been quite valuable as we establish SPARK in the marketplace.”

Digital Twins for AI in Healthcare

Probius relies on MATLAB and many of its toolboxes. Most crucially, it uses machine learning tools to train neural networks or genetic algorithms that can identify specific molecules within a sample’s signature. It also uses MATLAB to study the performance of its chip, optimize its manufacturing workflow, manage its computing cluster, and package its software into a docker for customers to use on a server.

Another Silicon Catalyst member is Probius, a startup making biochemical data easier to access and easier to use in artificial intelligence (AI) workflows. Typically, if you want to know if a biological sample—from a person or a cell culture—contains a particular molecule, you’d run a focused test looking for that molecule. Identifying a second one requires a second, completely different test. “All of this is based on a complex workflow, advanced expertise in the management and use of analytical tools, and reagents that are very specific to the analysis that you’re trying to perform. The direct consequence is a delay for information from a repetitive trial-and-error approach, which leads to an inaccurate and incomplete representation of the biology of the sample in the end,” says Emmanuel Quevy, Probius’ co-founder and CEO. “We are flipping the script completely.”

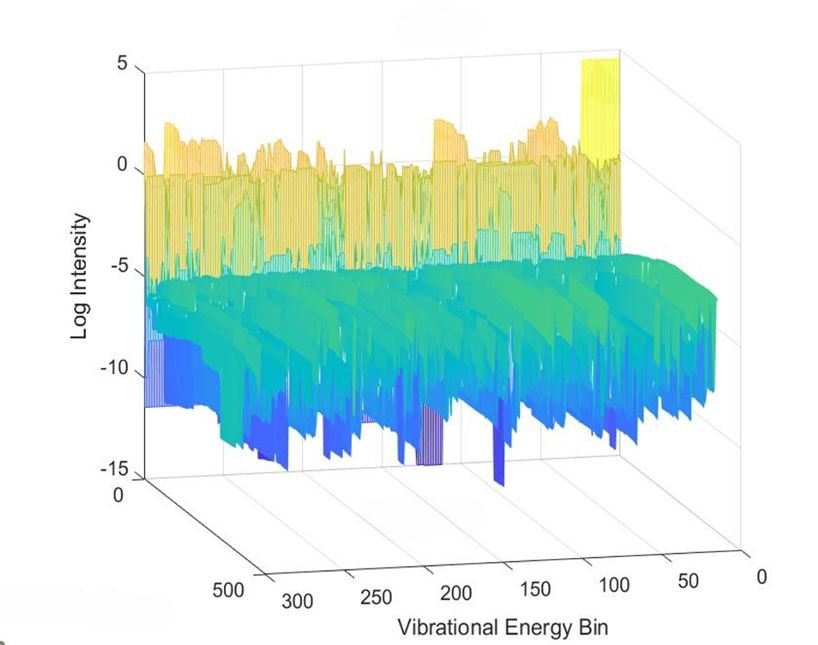

Probius developed a technology called Quantum Electrochemical Spectroscopy (QES) that scans the sample for all biochemical signals at once, creating a digital twin that can be probed on demand later. It relies on the fact that molecules vibrate, and they do so at different frequencies depending on their structure and composition. QES creates a 40-dimensional snapshot of a sample’s vibrational signature.

Probius uses machine learning to classify signatures as indicating different diseases. The technology enables Probius to identify individual molecules and their concentrations from the signature. From that 40-dimensional signature, Probius can zero in on the composition of thousands of different analytes, including proteins, viruses, drugs, and sugars. It has tested blood, food, lab cultures, and other samples. The test requires only a few millionths of a liter of the sample and takes half an hour.

Probius developed a chip and a device. For a subscription fee, customers rent the device and have access to analysis software and analytes on demand in the cloud. Customers include pharmaceutical companies, biotech startups, and academic labs. Some use the service to profile diseases like mechanisms of inflammation, for example. Others use it to optimize the manufacturing of bio products or therapeutics.

Juan Cruz Cuevas, who heads Probius’ marketing and business development, says the device makes sample analysis very accessible. “The QES platform requires one step to acquire the data. You put a drop of your sample inside the vial. That’s it.” It doesn’t even have buttons, and it uploads the data automatically. You move fast on the lab and spend time finding data insights instead.

Data analysis in MATLAB helps Probius visualize results, such as this MATLAB 3D surface plot of a QES vibrational signal of a human inflammation protein (TNF-a).

(Image credit: Probius)

Quevy says Probius relies on MATLAB and many of its toolboxes. Most crucially, it uses machine learning tools to train neural networks or genetic algorithms that can identify specific molecules within a sample’s signature. It also uses MATLAB to study the performance of its chip, optimize its manufacturing workflow, manage its computing cluster, and package its software into a docker for customers to use on a server.

Data analysis in MATLAB helps Probius visualize results using cluster plots, heat maps, dendrograms, and so on. “With MATLAB, you have an integrated library of pretty much all the machine learning and visualization tools that are out there and can leverage that to generate insights about biological samples without having to reinvent the wheel,” Quevy says.

Silicon Catalyst has helped Probius with funding and networking, but Probius was already using MATLAB. “You start training in school, and MATLAB follows you through your entire career,” Quevy says. “And as the company evolves and the tools evolve, you keep up to date.”

Probius worked with consultants at MathWorks to better use the tools, for example, to smooth out the workflow. Quevy says that without MATLAB, Probius could potentially run its algorithms in C, but MATLAB offers more flexibility to upgrade its analytical toolkit.

Such flexibility and ease of use is essential for a startup, Cuevas says. Even with limited resources and personnel, “we were able to move faster and to be more nimble and more effective.”

A Recipe for Success

Silicon Catalyst not only has a unique focus on silicon-based startups, but the firm also has a different model for supporting its members. “Most incubators have a cookie-cutter program,” says Pete Rodriguez, Silicon Catalyst’s CEO. “They dole out the same set of advice to startups over the course of a few months.”

Silicon Catalyst is different, he says. It starts with a rigorous selection process, which takes from four to 17 meetings over the course of six weeks. Silicon Catalyst has admitted only 100 companies out of 1,000 applicants. This highly selective approach combined with hands-on support from industry experts is the recipe for success for silicon-based startups.